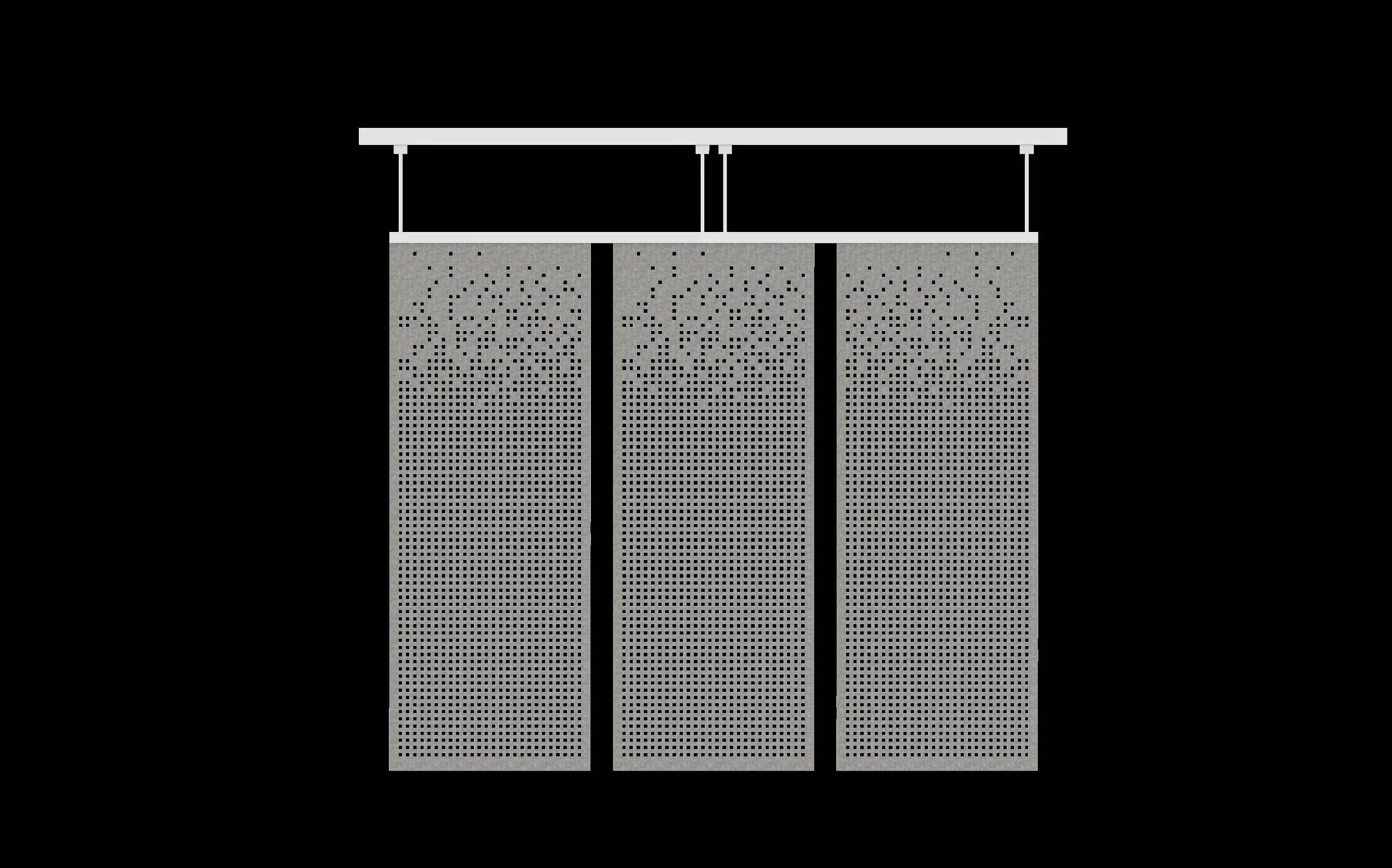

مصنع أرائك مناطق الانتظار في المكاتب

تمثل مصنع أرائك مكاتب منطقة الانتظار منشأة تصنيع متخصصة تُعنى بإنتاج حلول جلوس عالية الجودة مصممة خصيصًا للبيئات المهنية ومناطق الاستقبال. وتتمحور هذه المنشآت التصنيعية حول إنتاج قطع أثاث مريحة ومتينة وجذابة بصريًا، تؤدي غرضين معًا: توفير مقاعد مريحة وتعزيز المظهر المهني لمساحات المكاتب والمرافق الطبية وردهات الشركات والمنشآت التجارية المختلفة. ويستخدم مصنع أرائك مكاتب منطقة الانتظار تقنيات تصنيع متقدمة ومواد أولية فاخرة ومبادئ تصميم مريحة لتوفير منتجات تلبي المتطلبات الصارمة للبيئات التجارية الحديثة. وتشمل الوظيفة الأساسية لهذه المصانع الإنتاج المنظم لمختلف تكوينات المقاعد، بما في ذلك الأرائك الثنائية والثلاثية وأنظمة الأرائك الوحدوية التي يمكن تخصيصها وفقًا لمتطلبات المساحة المحددة والتفضيلات التصميمية. وتدمج هذه المنشآت تقنيات حديثة مثل برامج التصميم بمساعدة الحاسوب، وأجهزة قطع دقيقة، وأنظمة تجميع آليّة، وبروتوكولات ضبط الجودة لضمان التميز المنتج بشكل ثابت. وتشمل السمات التقنية أنظمة حقن رغوة متقدمة تُنتج كثافة وسائد مثالية، وتقنيات تنجيد دقيقة تكفل تطبيق القماش بدون عيوب، وأساليب بناء إطارات قوية تضمن دوام طويل الأمد. وتستخدم مصانع أرائك مكاتب منطقة الانتظار الحديثة عمليات تصنيع مستدامة، حيث تدمج مواد صديقة للبيئة وطرق إنتاج فعالة من حيث استهلاك الطاقة للحد من الأثر البيئي مع الحفاظ على جودة منتجات ممتازة. وتمتد تطبيقات منتجات مصنع أرائك مكاتب منطقة الانتظار عبر قطاعات عديدة تشمل المكاتب المؤسسية، والمرافق الصحية، والمؤسسات التعليمية، والمباني الحكومية، والفنادق، والمطارات، والمنشآت التجارية، حيث يُعدّ إيجاد أجواء مرحبة ومهنية أمرًا أساسيًا لنجاح الأعمال.